The Versatility of Slotted Aluminium Extrusions: From Robotics to Camper Van Renovations

In today's ever-evolving world, the need for versatile and adaptable building materials is greater than ever. From industrial automation to home renovation projects, the ability to create custom designs and structures is a must. Slotted aluminium extrusions offer a perfect solution for this need. These extrusions provide a lightweight yet durable foundation for a wide range of projects. They are easy to work with, easy to customize, and easy to install. They can be used for both indoor and outdoor applications, and their resistance to corrosion makes them ideal for any environment. In this blog, we'll take a closer look at the versatility of slotted aluminium extrusions and the many ways they can be used.

What are slotted aluminium extrusions?

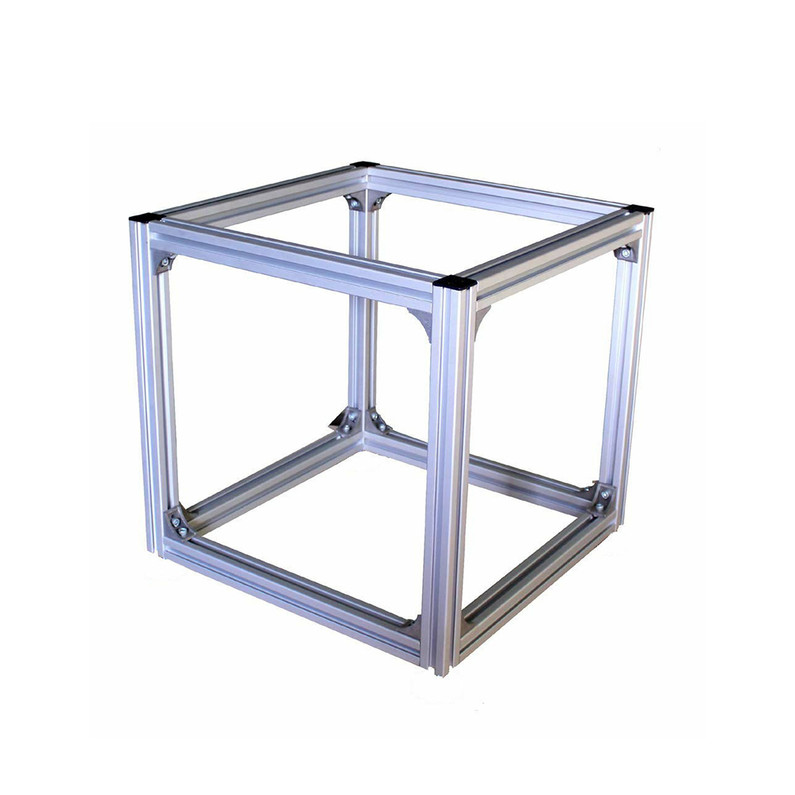

Slotted aluminium extrusions are long, narrow pieces of aluminium that have been shaped and cut to precise measurements. They are typically created through a process known as "extrusion," where heated aluminium is forced through a die in order to take on the desired shape. Slotted aluminium extrusions have one or more slots or grooves that run the length of the piece, allowing for the insertion of other materials or components. These extrusions can be used for a wide range of applications, including construction, manufacturing, and DIY projects. They are known for their strength, durability, and versatility, making them an excellent choice for a wide range of projects.

The versatility of slotted aluminium extrusions

The versatility of slotted aluminium extrusions is one of the reasons why they are so popular for a wide range of projects and applications. They are lightweight yet strong, making them perfect for use in many different industries. They also have a high level of resistance to rust and corrosion which makes them ideal for use in outdoor environments.

One of the main advantages of slotted aluminium extrusions is their ability to be easily modified or customized. This allows them to be used for a wide variety of projects and applications, from robotics and industrial automation to camper van renovations and DIY projects. Additionally, the slotted design of the extrusions allows for easy integration with other materials and components, making them an ideal choice for projects that require multiple components to work together.

II. Robotics and Industrial Automation

How slotted aluminium extrusions are used in robotics

One potential robotics project that could utilize 20mm square aluminium extrusions and components is building a small humanoid robot.

The extrusion itself, made of aluminium, offers a strong and lightweight framing solution for the robot's body and limbs. The 20mm size is perfect for sturdy DIY projects and robots, while still being compact and easy to work with.

Using T-nuts that slide into the slots on the extrusion, plates, couplers, PCBs, and cut-outs can be easily connected to construct the robot's body and limbs. The T-nuts, screws, and plates can be used to build a frame for the robot, and end-caps can be added to give it a finished look.

The length of the extrusion can be easily cut down with a hacksaw or bandsaw to the specific size needed for the project, so it is easy to get the exact size required.

Overall, using 20mm square aluminium extrusions and components in a robotics project, such as building a small humanoid robot, offers a strong, lightweight, and customizable framing solution that is easy to work with and can be tailored to the specific needs of the project.

Some Robotics projects using slotted aluminium extrusions

DIY Robot Arm:

This project involves building a robotic arm using 20mm square aluminium extrusions and components. The extrusions can be used to construct the robot's arm segments, providing a strong and lightweight structure for the motors and other components. T-nuts can be used to connect the plates, couplers, and PCBs, while screws and end-caps can be used to finish off the arm.

Build your own Robotics Chassis:

Building your own robotics chassis is easy and intuitive with slotted aluminium extrusions. All you need to get started are some aluminium extrusions (whichever size suits your project - they can also be cut to length with a hacksaw), some brackets and some screws and t-nuts to hold the whole thing together. The aluminium profiles offer good strength and stiffness while being lightweight, inexpensive and corrosion-resistant. They are also easy to modify and adjust, so you can make changes to your robotics chassis as needed.

One of the key benefits of using slotted aluminium extrusions for your robotics chassis is that they are very easy to dissassemble. This makes them uniquely perfect for constructing something that may need to be partially taken apart for storage or transportation.

Robotic Gripper:

Building a robotic gripper with 20mm square aluminium extrusion and components is a fast and easy process. Start by selecting the length of the aluminium extrusion that you need for your robotic gripper. If the exact size you need is not available, don't worry - you can easily cut down the extrusion with a hacksaw or bandsaw. Next, grab some T-nuts, screws, and plates to build the frame of your robotic gripper. The T-nuts slide into the 6mm slots on the aluminium extrusion, allowing you to connect the plates, couplers, and other components. Assemble the frame of the gripper using the T-nuts, screws, and plates, making sure that everything is securely fastened together. Once the frame is assembled, you can add any additional components that you need to complete your robotic gripper. This may include actuators, sensors, or other electronics. To finish off your gripper, add end-caps to the extrusion's ends. These not only give it a more polished look, but also protect the ends of the aluminium extrusion. Once completed, test your gripper and make any adjustments or tweaks as needed.

Linear Actuator:

Slotted aluminium extrusion - 20mm x 20mm is an ideal option to create a project of linear actuator, as it provides good strength and stiffness, is lightweight, has 6mm slots for easy assembly, can be customized to size and shape and is corrosion-resistant, making it durable. With the T-nuts, screws and plates the frame of the linear actuator can be easily assembled, once the frame is built, it's easy to add any additional components such as sensors, actuators, or other electronics.

Robot for Agriculture:

The slotted aluminium extrusions can be used to construct the frame and other components of a robot designed for use in agriculture, providing a durable and customizable solution for tasks such as crop monitoring and harvesting. T-nuts can be inserted into the slots of the extrusions, allowing for a secure and stable connection of plates, couplers, and PCBs, while screws and end-caps can be used to finish off.

All of the projects above are just examples of what you can create using 20mm square aluminium extrusions and components. With the help of T-nuts, screws, and end-caps, you can create a wide range of projects to suit your needs.

Camper Van Renovations

How slotted aluminium extrusions are used in camper van renovations

20mm square aluminium extrusions and components can be used in a variety of ways in camper van renovations. Here are a few examples:

Cabinets and Shelving:

Upgrade your camper van storage with sleek and durable aluminium extrusion frames. These frames offer a sturdy and lightweight solution for all your storage needs, and can be easily customized to fit your specific requirements.

By using T-nuts, plates, couplers, and PCBs, you can easily connect and build your desired storage configuration. And with the added touch of screws and end-caps, your storage will not only be functional, but also have a polished and finished look.

Whether you need to store clothes, food, or equipment, these aluminium extrusion frames are the perfect solution for maximizing space and organization in your camper van. So, if you're looking for a storage upgrade that is both practical and visually appealing, give aluminium extrusion frames a try!

Bed Frame:

Create a durable and lightweight foundation for your camper van bed using aluminium extrusion. Assemble the frame using T-nuts to connect the plates, couplers, and PCBs, and finish it off with screws and end caps.

Kitchen Countertop:

Elevate your camper van kitchen with a sleek and sturdy countertop made with aluminium extrusion. Use T-nuts to connect the plates, couplers and PCBs, and finish off the look with screws and end-caps.

Shower Unit:

Experience luxury on the road with a custom-built shower unit using aluminium extrusion. Assemble the frame with T-nuts, connect the plates, couplers, and PCBs and finish it off with screws and end caps.

Roof Rack:

Upgrade your camper van's carrying capacity with a robust and lightweight aluminium extrusion roof rack. Connect the plates, couplers, and PCBs with T-nuts, and finish it off with screws and end caps.

With 20mm aluminium extrusions and components strength, lightweight and easy customizability, they can be used in countless ways to create a wide range of structures and fittings for a camper van.

Conclusion

Slotted aluminium extrusions are the perfect choice for a wide range of projects, from construction and manufacturing to DIY projects. They are versatile, strong, and durable, and have a high level of resistance to rust and corrosion. Plus, their ability to be easily modified or customized makes them ideal for a wide variety of applications. Whether you're building a robot, a camper van or a bookshelf, slotted aluminium extrusions are the way to go!

Recent Posts

-

What is Ohm's Law?

Are you curious about how electricity works? Let me introduce you to a very important concept i …9th Mar 2023 -

How do I control a central heating system using an Arduino

To control a heating system using an Arduino, you will need to write a sketch (program) that impleme …7th Feb 2023 -

The Versatility of Slotted Aluminium Extrusions: From Robotics to Camper Van Renovations

In today's ever-evolving world, the need for versatile and adaptable building materials is greater t …25th Jan 2023